Views: 0 Author: Site Editor Publish Time: 2025-12-10 Origin: Site

Wood–plastic composite (WPC) profiles have become one of the most widely used materials in modern building, outdoor landscaping, and decorative applications. Their ability to offer the look of natural wood while delivering superior durability, weather resistance, and low maintenance makes them a popular choice for manufacturers and end users alike.

This comprehensive guide explains everything you need to know about WPC profile production—from raw materials and manufacturing processes to machinery selection and real-world applications. The content is also tailored for readers researching WPC production equipment, featuring a practical example: Anda Machinery’s WPC Profile & Decking Manufacturing Production Line.

WPC profiles are engineered building materials made from a blend of wood fibers and thermoplastic polymers such as PE, PP, or PVC. When these ingredients melt and mix together, they create a composite that looks like wood but performs far better in demanding environments. It lasts longer, stays stable outdoors, and needs almost no maintenance.

What WPC Profiles Are Made Of

WPC combines organic and synthetic ingredients. Below is a simplified breakdown of what typically goes into a WPC formulation:

| Component | Function | Notes |

|---|---|---|

| Wood Powder / Fiber | Adds rigidity, natural texture | Often recycled or milled wood residue |

| Plastic Resin (PE/PP/PVC) | Provides strength, water resistance | Can be virgin or recycled material |

| Additives | Improves color, durability, stability | Includes pigments, stabilizers, lubricants |

The mix delivers a strong material that behaves much more predictably than natural wood.

Why Manufacturers Use WPC Profiles

People choose WPC profiles for many reasons. They offer the look of wood but remove nearly all the headaches tied to real lumber. Here are some of the biggest advantages:

Moisture resistance — It won't absorb water or swell in humid conditions.

Weather toughness — Rain, sun, heat, or cold doesn’t break it down easily.

No termites — Insects avoid it because the plastic matrix protects the wood fiber.

Low maintenance — No painting, sealing, or re-coating needed.

Eco-friendly — Many factories use recycled plastics and wood waste, reducing environmental impact.

Shape flexibility — Molds can produce decking, cladding, fencing, door frames and more.

Where WPC Profiles Are Used

WPC profiles show up in many places around homes, commercial buildings, parks and outdoor landscapes. They’re popular in:

Decking boards for patios and walkways

Exterior wall cladding

Garden fencing, railing, pergolas

Indoor trim, door frames, decorative profiles

Furniture components and small construction parts

Each shape comes from a dedicated extrusion mold, making the material incredibly adaptable.

How WPC Differs From Traditional Wood

Wood looks great, but it reacts constantly to its environment. It warps, rots, cracks and attracts bugs. WPC solves these problems by encapsulating wood fiber inside a plastic matrix. So profiles stay straighter and last longer.

| Feature | Natural Wood | WPC Profile |

|---|---|---|

| Water Resistance | Poor | Excellent |

| Maintenance | High | Very Low |

| Insect Damage | Common | Rare |

| Lifespan | Moderate | Long |

| Design Flexibility | Limited | High |

Because of these improvements, WPC is replacing wood in many industries.

What Makes WPC Profiles Important Today

Construction trends are shifting. Builders want durable materials. Homeowners want low-maintenance products. Manufacturers want recyclable, low-waste options. WPC meets all three goals. It saves time, cuts long-term costs, and opens new design possibilities. The world demands smarter materials, and WPC is one of them.

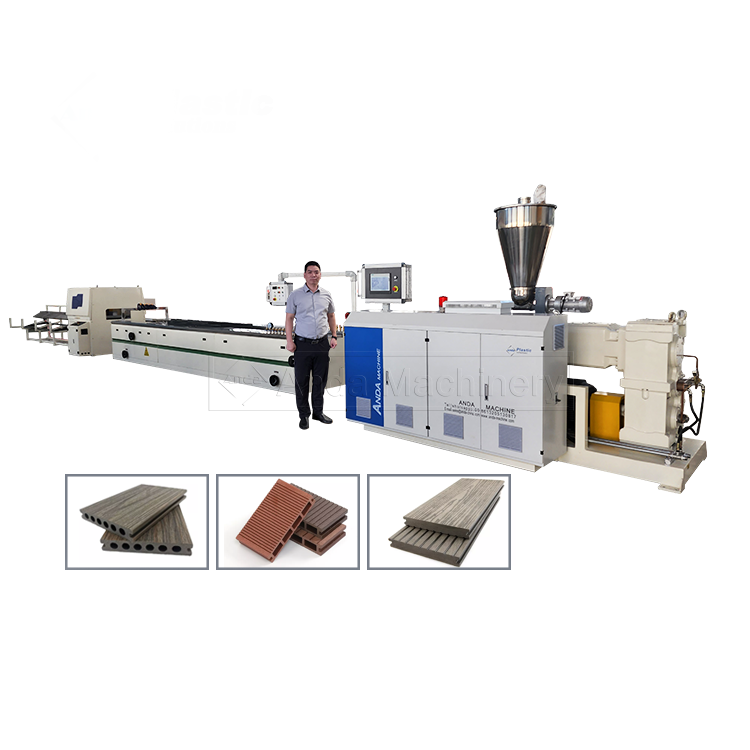

A WPC profile production line looks complex at first, but each part has a simple job. When all components work together, they turn mixed raw materials into strong, finished WPC profiles. The line runs continuously, so every section must stay steady and predictable.

Main Parts of a WPC Production Line

Below is a quick look at the major equipment used throughout the process:

| Component | What It Does | Why It Matters |

|---|---|---|

| Feeding & Dosing System | Moves materials into the extruder | Keeps ratios consistent |

| Twin-Screw Extruder | Melts and mixes wood fiber + plastic | Creates uniform material |

| Extrusion Die / Mold | Shapes the profile | Defines final cross-section |

| Vacuum Calibration Table | Stabilizes hot material | Controls dimensions |

| Cooling System | Lowers temperature gradually | Prevents bending |

| Haul-Off Machine | Pulls profile forward | Maintains speed and thickness |

| Cutting Unit | Cuts profiles to length | Ensures accuracy |

| Stacker | Collects finished pieces | Keeps workflow organized |

Each part plays its own role. When one section slips, the whole line feels it.

How the Production Line Works Step by Step

The line follows a smooth, repeatable sequence. Here’s an easy diagram-style breakdown:

Wood powder, plastic pellets, and additives mix until they look uniform.

A controlled system pushes the blend forward at a constant rate.

Inside the twin-screw extruder, heat zones and screw motion melt everything. It forms a thick, smooth melt.

It gets pressed through a mold opening that creates the profile’s shape.

The hot piece enters a calibration table. Vacuum pressure helps it stay straight and stable.

Water or air cooling brings the temperature down in stages.

The haul-off machine keeps everything moving evenly.

A saw unit trims the board or panel to the desired size.

Finished profiles move onto a collection table.

Why the Twin-Screw Extruder Is the “Heart” of the Line

The extruder mixes wood and plastic so completely that the final profile stays strong. Here’s why manufacturers rely on it:

It offers high shear mixing for better melt quality.

It handles formulas containing large amounts of wood powder.

It maintains temperature stability across zones.

It creates uniform output for long runs.

Optional Add-Ons That Improve Production

Many factories add extra equipment. It helps expand product styles or boost efficiency:

Embossing units for wood-grain textures

Brushing machines for matte or rustic finishes

Co-extrusion systems for multi-layer profiles

Online monitoring systems for faster quality checks

These options make the line more flexible. It can produce decking, wall panels, fencing boards, or decorative trims without major changes.

A Simple Flowchart of the Entire Process

Raw Material Mixing → Feeding → Twin-Screw Extrusion → Die Shaping → Vacuum Calibration → Cooling → Haul-Off → Cutting → Stacking & Storage

Every stage pushes the next. The smoother each part runs, the better the finished WPC profile looks.

The WPC profile production process involves several carefully controlled stages. With a modern production line, such as that from Anda Machinery, the workflow is efficient and highly automated.

Wood powder, plastic resin, and additives are weighed and mixed to meet formulation requirements. Proper drying and accurate dosing are essential for stable production.

The mixed materials are fed into the extruder. Manufacturers may use a one-step or two-step process, depending on product requirements and material characteristics.

The conical twin-screw extruder melts and compounds the materials under precisely controlled temperatures.

PID temperature control ensures consistent melt quality, preventing wood fiber degradation or uneven plasticizing.

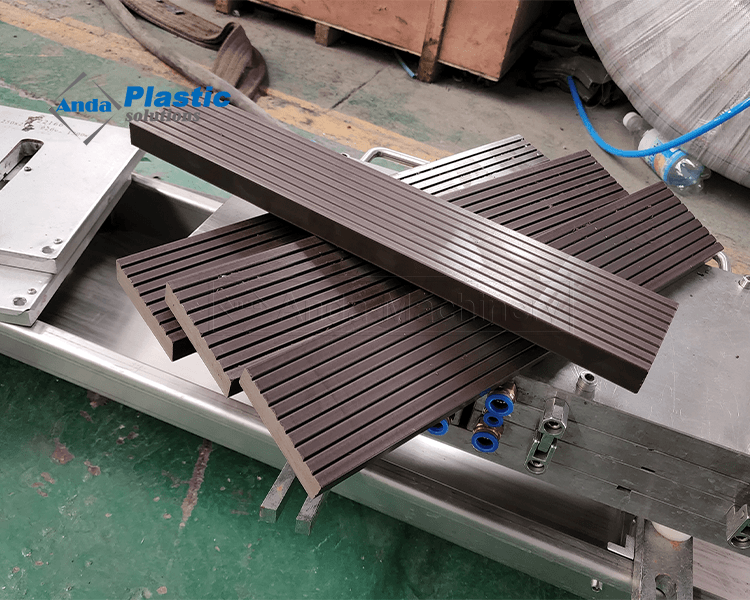

The molten WPC material flows through a profile die, forming the exact cross-sectional shape of the decking board, wall panel, or other profile.

A vacuum calibration table cools the profile uniformly, maintaining straightness and consistent dimensions.

Anda Machinery’s vacuum cooling system delivers high stability, even for thick decking boards.

A synchronized haul-off pulls the profile at a controlled speed.

The cutting machine trims the product to the exact length, ensuring precision and repeatability.

Depending on the application, profiles may undergo:

Wood-grain embossing

Brushing or sanding

Texture enhancement

UV-protective surface layers (co-extrusion)

This step improves both appearance and performance.

Producing consistent and high-quality WPC profiles requires precise control over multiple variables.

Wood powder size and purity

Plastic quality (virgin or recycled)

Effectiveness of additives

Proper formulation ratio (wood-to-plastic balance)

Temperature uniformity

Screw design and rotation speed

Melt pressure stability

Haul-off synchronization

Anda Machinery’s intelligent inverter-driven systems ensure smooth speed adjustment and energy efficiency, reducing defects caused by inconsistent extrusion.

Uniform cooling prevents:

Bending

Internal stress

Shrinkage defects

High-quality molds produce smoother surfaces and more accurate profile dimensions.

Regular cleaning, lubrication, and calibration minimize wear and ensure long-term performance.

Manufacturers may choose from several extrusion line configurations depending on product type, scale, and budget.

Best overall mixing performance

Ideal for decking, wall panels, pergolas, decorative trims

Handles high wood content formulations efficiently

Most widely used in medium-to-large-scale factories

Lower cost

Suitable for specific profile types or smaller factories

Less effective for heavy wood-filled materials

Produce multi-layer profiles

Surface layer may include UV protection, color enhancement, or anti-scratch properties

Essential for premium outdoor WPC decking products

Anda Machinery offers all major WPC configurations, supporting both standard and co-extruded WPC profiles.

A high-quality WPC profile production line can manufacture products for diversified markets, such as:

Outdoor decking boards

Exterior wall cladding and façade panels

Garden fencing and railing systems

Pergola beams and landscaping components

Door frames and interior decorative trims

Interior wall panels and baseboards

Industrial and construction profiles

This flexibility allows manufacturers to target both indoor and outdoor markets with a single production line—simply by changing molds and optional finishing systems.

When choosing a WPC production line, manufacturers should consider:

Decking, panels, fences, interior trims, multi-layer profiles, etc.

Daily/weekly output expectations.

Ability to handle PE, PP, PVC, or recycled materials.

Systems like ABB frequency inverters and PLC/PID temperature control improve efficiency.

Anda Machinery’s WPC production lines are designed for lower operating energy, reducing cost per kilogram produced.

Essential for producing different shapes and designs.

Installation guidance, spare parts, and long-term service availability.

A line such as Anda Machinery’s WPC Profile Decking Manufacturing Machine is ideal for factories seeking reliable performance, scalability, and cost efficiency.

WPC profile production is a rapidly expanding sector, driven by demand for sustainable, durable, and low-maintenance building materials. A modern WPC extrusion line—especially one engineered for stability, precision, and energy efficiency—offers manufacturers a competitive advantage and long-term business opportunity.

By selecting a high-quality production line such as the system offered by Anda Machinery, manufacturers can produce a wide range of WPC profiles with consistent quality, attractive finishes, and excellent outdoor performance.

If your factory is planning to upgrade or expand its WPC production capabilities, investing in a reliable, flexible, and energy-efficient extrusion line is the key to success in today’s composite materials market.