PVC imitation marble sheet production lineis used to produce PVC marble sheet with a width of 1220mm and a length of 2440mm. The thickness is mostly 2.8 to 3.5mm. The surface of the PVC marble sheet is generally treated by hot stamping or lamination and then coated with UV varnish. By switching films with different colors, it can produce PVC marble sheets with different colors. After coating with UV glossy varnish, the surface of the PVC marble sheet is more smooth and wearable.

This machine can also produce LVT flooring by some adjustments and with related auxiliary machines. PVC marble sheet is widely used in hotels, office buildings, supermarkets, KTV, massage clubs and other public areas. Compared with natural marble boards and MDF sheets, it has such features and advantages: 1. Lower cost; 2. Waterproof, insect-proof, and mothproof; 3. Easy and faster installation; 4. Vivid color and glossiness; 5. Environmental protection and no pollution.

PVC Marble Sheet Production Line

PVC Artificial Marble Sheet/Wall Panel/Interior Decoration Board Production Line is used to make PVC imitation marble sheet which has marble, carpet, stones, natural scenery, and stereo designs on the surface. And the board is popular in hospitals, schools, office buildings, shopping malls, supermarkets, transportation and other public places.

Product Advantages

High output

One production line can produce at least 530 pieces per day. The speed is controlled by the inverter, which saves electricity and is easy to adjust the speed. The extruder temperature is automatically adjusted by the Omron smart controller temperature function. It can also be equipped with a PLC touch screen according to customer preferences.

Processing Flow

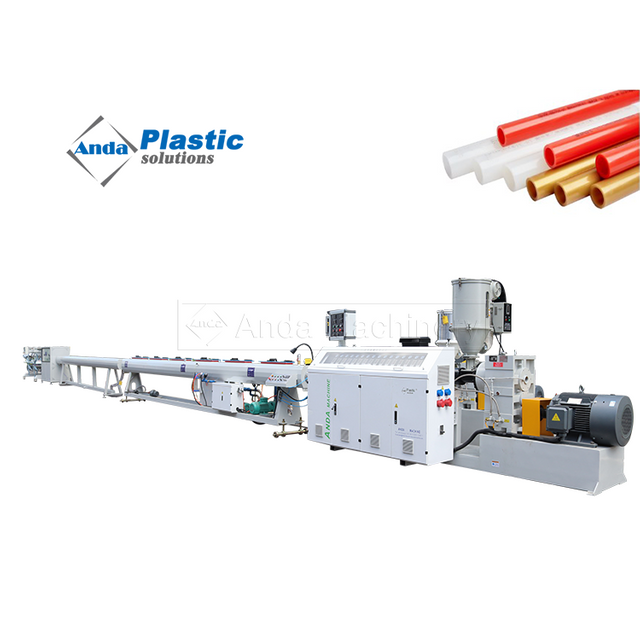

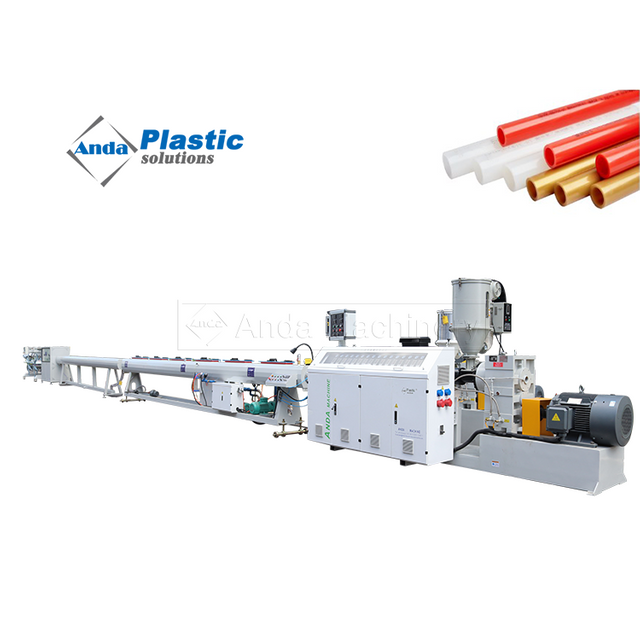

500/1000l mixer → automatic feeder → SJSZ80/156 conical twin-screw extruder → mold → three calenders (online laminating) → trimming machine → coiler → cross-cutting machine → conveyor → UV treatment → final PVC marble slab.

pvc marble profile production line Application

Mainly used in home decoration background walls, walls, hotels, KTVs, shopping malls, entertainment venues and other interior wall decoration project places. It is an alternative to artificial stone, marble tiles, wood veneer panels and other wall materials.

The PVC Marble Sheet Production Line from Anda Machinery represents a leap forward in interior wall decoration technology. By combining beauty, durability, and cost-efficiency, these sheets are set to revolutionize how designers and architects approach interior spaces. Whether for homes, hotels, or commercial venues, PVC marble sheets provide an unparalleled solution that meets the demands of modern design.

FAQs

What is the PVC Marble Sheet Production Line?

The PVC Marble Sheet Production Line is an advanced manufacturing system designed to produce high-quality PVC sheets that mimic the luxurious look of marble. These sheets are versatile and can be used in a variety of interior decoration projects, offering an affordable and durable alternative to natural stone.

How does the production line ensure high quality?

Our production line incorporates world-class components and cutting-edge technology. It features a conical twin-screw extruder, vacuum calibration, hauling equipment, and a cutting machine. This ensures that each sheet is produced with precision, maintaining consistency in thickness, color, and texture.

Is the installation of PVC marble sheets straightforward?

Yes, the installation process is designed to be simple and efficient. The sheets are lightweight and easy to handle, making them a convenient choice for quick renovations and new projects.

What are the advantages of using PVC marble sheets over natural marble?

PVC marble sheets offer several benefits over natural marble, including cost-effectiveness, ease of installation, and reduced maintenance. They are also more resistant to stains and scratches, making them ideal for high-traffic areas.

Related Blogs

-

2026 Comparison of PVC Edge Banding and ABS Edge Banding

2026 Comparison of PVC Edge Banding and ABS Edge BandingChoosing the right edge banding is important. In 2026, ABS edge banding is best for high-quality and green projects. PVC Edge Band is still used for cheaper jobs. ABS is strong and good for the environment. It can take a lot of pressure and is easy to recycle. PVC is good for daily use and costs les

-

How Is PVC Pipe Extruded?

How Is PVC Pipe Extruded?PVC pipes are essential in modern infrastructure, used in everything from plumbing to electrical conduits. But have you ever wondered how they are made? The process behind PVC pipe production, known as extrusion, is key to their durability and versatility. In this article, we will explore the stages of PVC pipe extrusion and how this process ensures consistent, high-quality products. You will gain a deeper understanding of why extrusion is crucial for producing reliable and long-lasting PVC pipes.

-

What Is A PVC Extruder?

What Is A PVC Extruder?Have you ever wondered how everyday products like pipes, window frames, and cable insulation are made? The answer lies in the PVC extruder, a vital machine in modern plastic manufacturing. PVC extruders melt and shape polyvinyl chloride (PVC) into continuous products, ensuring consistency and quality across industries.

-

What Is A Plastic Extruder Machine?

What Is A Plastic Extruder Machine?Have you ever wondered how plastic pipes, sheets, or even profiles are made in mass production? The answer lies in a plastic extruder machine. This essential piece of equipment is used to melt raw plastic and shape it into continuous forms. In industries ranging from construction to packaging, plastic extruders play a critical role in creating a wide variety of products.

-

What Is The Extrusion Process in Plastics?

What Is The Extrusion Process in Plastics?Plastic extrusion plays a crucial role in creating products we use daily, from pipes to films. But how does this process work? Why is it essential in manufacturing? In this article, we will explore the extrusion process in plastics, its key components, and how it creates products with consistent shapes. You’ll also learn about the role of additives and the advantages of extrusion in industries such as packaging, construction, and medical.

-

Industrial Electricity (three-phase Electricity) Voltage And Frequency Parameters in Various Countries Around The World

Industrial Electricity (three-phase Electricity) Voltage And Frequency Parameters in Various Countries Around The WorldAs the export of pipeline pump products increases, different voltages in different countries require customized motors of various types. This article lists the three-phase electricity voltage and frequency around the world.Please note that since three-phase electricity is rarely used for household p

-

Ceiling Panel Production: Complete Guide To Processes, Materials, Machinery & High-Efficiency PVC Panel Production Lines

Ceiling Panel Production: Complete Guide To Processes, Materials, Machinery & High-Efficiency PVC Panel Production LinesCeiling panel production has grown into one of the most profitable sectors in construction materials manufacturing. As global demand for modern, durable, low-maintenance interiors rises, PVC ceiling and wall panels have become a preferred choice for residential, commercial, and industrial projects.W

English

English