Views: 0 Author: Site Editor Publish Time: 2025-12-10 Origin: Site

Ceiling panel production has grown into one of the most profitable sectors in construction materials manufacturing. As global demand for modern, durable, low-maintenance interiors rises, PVC ceiling and wall panels have become a preferred choice for residential, commercial, and industrial projects.

Whether you are a new investor or an experienced factory owner looking to scale production, understanding the complete ceiling panel manufacturing process — and choosing the right production line — is essential for achieving competitive product quality, low production cost, and long-term profitability.

In this comprehensive guide, we break down everything you need to know about ceiling panel production, including:

How ceiling panels are manufactured

Types of materials and products

Step-by-step production workflow

Essential machinery in a complete production line

Power efficiency and stability considerations

How to choose the right panel-making machine

Why Anda Machinery’s PVC Ceiling Panel Production Line is a top industry solution

This article also introduces topics of interest to many, such as ceiling panel production, PVC ceiling panel production line, panel manufacturing machine, and PVC ceiling machine, helping readers understand the ceiling manufacturing industry and make informed choices when selecting PVC ceiling machines.

Ceiling panel production refers to the industrial process of manufacturing decorative and functional panels used for covering ceilings and sometimes walls. These panels enhance interior design, improve insulation and acoustics, and protect surfaces from moisture, dirt, and damage.

Among all ceiling panel types, PVC ceiling panels stand out due to their:

Lightweight structure

Moisture resistance

Fire-resistant and anti-corrosion properties

Easy installation and long lifetime

Attractive surface finishes (lamination, hot stamping, printing)

Competitive production cost

The rising adoption of PVC ceiling and wall panel systems in homes, offices, restaurants, hotels, and retail spaces has significantly boosted demand for efficient production machinery.

Modern ceiling panel production covers several materials, each created for different design goals, durability needs, and installation environments. Manufacturers choose the panel type based on cost, performance, and market demand. Below is a clear breakdown of the most common ceiling panels used today.

PVC panels dominate the global market because they’re lightweight, affordable, and moisture-resistant. They work well in kitchens, bathrooms, offices, and commercial interiors.

They are produced through an extrusion process, often running continuously for long hours — similar to how prime-rated industrial systems operate efficiently for extended periods. This makes stable power supply important for factories using automated PVC extrusion lines.

Key advantages

Waterproof and mold-resistant

Easy to install and clean

Supports decorative finishes like hot stamping or lamination

Low material cost, especially when high CaCO₃ filler is used

Typical Applications

Homes

Commercial spaces

Hotels

Retail ceilings

Gypsum panels remain a popular choice where fire resistance and smooth surface finishes matter.

They need careful handling because the material can break under pressure, and manufacturers often rely on steady production conditions to avoid defects.

Pros

Excellent fire resistance

Good thermal and noise insulation

Smooth, paintable surface

Cons

Heavier than PVC

Sensitive to moisture

These panels appear often in acoustic environments. They help absorb sound and reduce echo. Manufacturers use controlled mixing and curing processes to keep density consistent.

Benefits

Strong acoustic performance

Suitable for large ceilings and grid systems

Fire-resistant

Common Uses

Schools

Office buildings

Auditoriums

Metal panels deliver strength, durability, and modern aesthetics. They’re made by feeding metal coils into forming machines, which shape and perforate them.

Factories producing metal panels typically operate under steady loads — similar to continuous power systems that maintain fixed output without fluctuation.

Highlights

Long lifespan

Corrosion-resistant when coated

Works well in industrial or high-traffic spaces

Limitations

Higher material cost

Requires specialized cutting and coating equipment

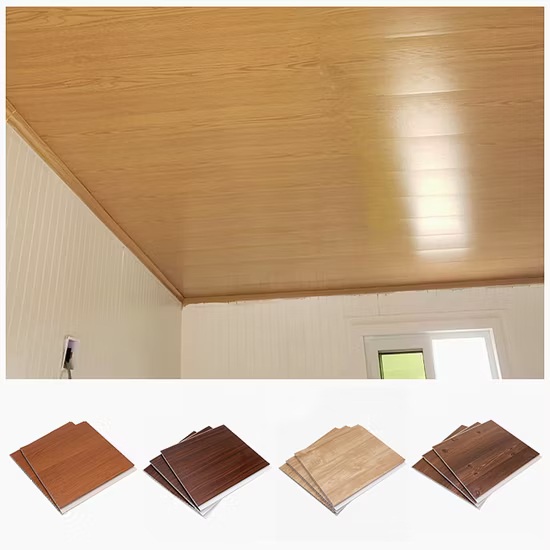

Wood composite and natural wood panels create warm, decorative surfaces. Production involves pressing, cutting, and coating, requiring precise environmental control.

Why people choose them

Natural appearance

Excellent design versatility

Challenges

Sensitive to humidity

Higher cost than PVC

| Panel Type | Moisture Resistance | Durability | Cost Level | Common Usage |

|---|---|---|---|---|

| PVC | ⭐⭐⭐⭐ | ⭐⭐⭐ | Low | Homes, offices, bathrooms |

| Gypsum | ⭐⭐ | ⭐⭐⭐ | Medium | Homes, fire-rated spaces |

| Mineral Fiber | ⭐⭐ | ⭐⭐ | Medium | Offices, acoustic rooms |

| Metal | ⭐⭐⭐⭐ | ⭐⭐⭐⭐ | High | Airports, malls, stations |

| Wood / WPC | ⭐⭐ | ⭐⭐⭐ | Medium-High | Decorative interiors |

While every panel type has unique requirements, PVC ceiling panel production is among the most efficient and widely adopted processes worldwide. Below is the standard workflow:

PVC resin is mixed with additives such as:

Calcium carbonate (CaCO₃)

Stabilizers

Lubricants

Colorants

High filler ratios reduce cost — a major advantage in competitive markets.

A twin-screw extruder melts and mixes the PVC material into a continuous profile.

Vacuum calibration ensures the panel maintains accurate shape and thickness.

This is the most critical stage for panel dimensional accuracy.

Panels pass through a cooling table with a vacuum system that stabilizes the profile and ensures a smooth, flat surface.

A haul-off machine pulls the formed panel through the line at a stable speed, while the cutting machine trims panels to the standard tile sizes (e.g. 595×595 mm, 600×600 mm, 603×603 mm).

Hot stamping

Lamination

Embossing

UV coating

Color printing

These add aesthetic value and broaden market appeal.

Panels must be protected from bending or scratching during storage and transport.

A complete panel-making production line typically includes:

Twin-screw extruder

Vacuum calibration & cooling table

Hot stamping / lamination machine

Haul-off system

Cutting machine

Stacker / packaging system

Electrical control cabinet (PLC / PID temperature system)

Each component plays a role in stabilizing flow, reducing defects, and optimizing output.

Industrial panel production lines operate continuously, requiring stable, reliable power. Energy cost is a major factor in overall profitability.

A high-quality production line should:

Maintain stable extrusion flow

Reduce electricity consumption

Minimize downtime

Support high-output manufacturing

Anda Machinery’s production line is engineered specifically with energy efficiency and stability in mind — making it ideal for manufacturers in regions where power cost is high.

Anda Machinery’s Complete PVC Ceiling Wall Panel Making Machine Production Line is one of the most advanced, efficient, and user-friendly solutions on the market.

Below are the features that make it a standout choice for ceiling panel manufacturers.

The Anda PVC panel production line achieves double the output of conventional machines.

This means:

Higher production capacity

Reduced labour requirements

Lower electricity consumption per unit

Faster return on investment (ROI)

The machine allows up to 300 phr filler, significantly reducing material cost while maintaining stable production performance.

This is highly advantageous for factories targeting budget-sensitive markets.

Thanks to advanced motor control, optimized heating systems, and high-precision screw design, Anda’s line saves 25–30% power compared with traditional machines.

The machine supports online hot stamping, enabling production of decorative patterns without extra downstream equipment.

This simplifies production and expands your product portfolio.

| Model | Panel Width Output | Daily Output Capacity |

|---|---|---|

| SJSZ65/132 | 595mm,600 mm,603mm | 4000-5000pcs / 24h |

| SJSZ80/156 | 595mm,600 mm,603mm | 10000pcs / 24h |

These capacities make Anda Machinery suitable for small, medium, and large manufacturers.

Anda Machinery is committed to helping manufacturers reduce production cost, improve efficiency, and produce higher-quality ceiling panels.

When selecting a ceiling panel production line, consider:

How many square meters per day do you want to produce?

Ceiling tiles? Wall panels? Laminated or printed surfaces?

If you plan to use high filler content, the extruder must handle it efficiently.

Electricity is a major cost factor; choose an energy-saving model.

A machine that breaks down frequently costs more than it saves.

Anda Machinery provides full installation support and operator training.

Solution: Stable extrusion + vacuum calibration table.

Solution: Infrared flow tracking system for consistent melt flow.

Solution: 25–30% energy-saving design.

Solution: High-efficiency double-out extrusion for double production.

Absolutely — especially with the right production line.

PVC ceiling panels offer:

Low raw material cost

High production yield

Strong market demand

Attractive margins (especially with decorative panels)

Factories using high-output lines like Anda Machinery often achieve ROI within 6–18 months depending on market size and product pricing.

Ceiling panel production — especially PVC panel manufacturing — is a rapidly growing sector with strong demand in construction and interior design. To remain competitive, manufacturers must invest in efficient, stable, high-output panel-making machines that reduce energy consumption and improve product quality.

Anda Machinery’s Complete PVC Ceiling Wall Panel Production Line delivers industry-leading performance, cost efficiency, and long-term reliability, making it one of the best solutions for manufacturers worldwide.

If you're planning to start or upgrade your ceiling panel production line, Anda Machinery offers the ideal combination of technology, performance, and value.

Interested in setting up your own ceiling panel factory?

Need a high-output, energy-saving PVC ceiling panel production line?

Contact Anda Machinery today for pricing, machine specifications, and professional production solutions.

Your success in ceiling panel manufacturing starts with choosing the right machine — and Anda delivers the performance your factory needs.