| Availability: | |

|---|---|

| Quantity: | |

China

JINSE

Anda Edge Banding Tape Manufacturing Machine

Built for durability, the edge banding tape manufacturing machine uses wear-resistant components in high-friction zones, reducing maintenance downtime by up to 40%. Its intuitive touchscreen interface simplifies operation, even for staff with minimal technical training. For businesses balancing speed, quality, and adaptability, this machine emerges as an indispensable asset in today’s competitive manufacturing landscape.

Main parameter of edge banding tape manufacturing machine

Model | SJSZ45 | SJSZ55 |

Extruder | 45/100 | 55/110 |

Output Cavities | 2 cavity | 4 cavity ,6 cavity or 8 cavity |

Capacity | 1.5-1.8 ton per day | 2.2 tons per day |

Company Profile

Anda company was established by professional, passionate & responsible peoples who has long time experience in china plastic machines industry, Since inception, Anda company team always believes that excellent product quality reasonable price and professional fast service is the basis for long term cooperation with our customers, Therefore, anda company apply very strict rule for quality, and make high standard level for product quality. At same time, we striving to reducepro-duction cost to offer better price to our customers, And, we also pay much attention to service, we consider service as importantas sales work, we continuously train cur service stuff, improve their service ability and service attitude, so that this team can provide in time, most professional service to each of our customer around the world.

Proven Reliability: Our equipment is manufactured with high-grade steel and imported components, undergoing rigorous quality testing to ensure stable performance under 24/7 operation.

Customization Capabilities: We collaborate with clients to design equipment tailored to their specific product needs—whether it’s custom profiles, unique textures, or specialized production capacities.

Global Compatibility: All machinery meets international standards (CE, ISO 9001) and supports universal voltage (220V/380V), making it suitable for export to Europe, Asia, Africa, the Middle East, and the Americas.

End-to-End Support: Our team provides pre-sales technical consultation, on-site installation, and after-sales maintenance (including spare parts supply within 48 hours for urgent needs), ensuring minimal downtime.

Cost-Effective Innovation: We combine advanced technology with competitive pricing, making high-performance production equipment accessible to SMEs and large enterprises alike.

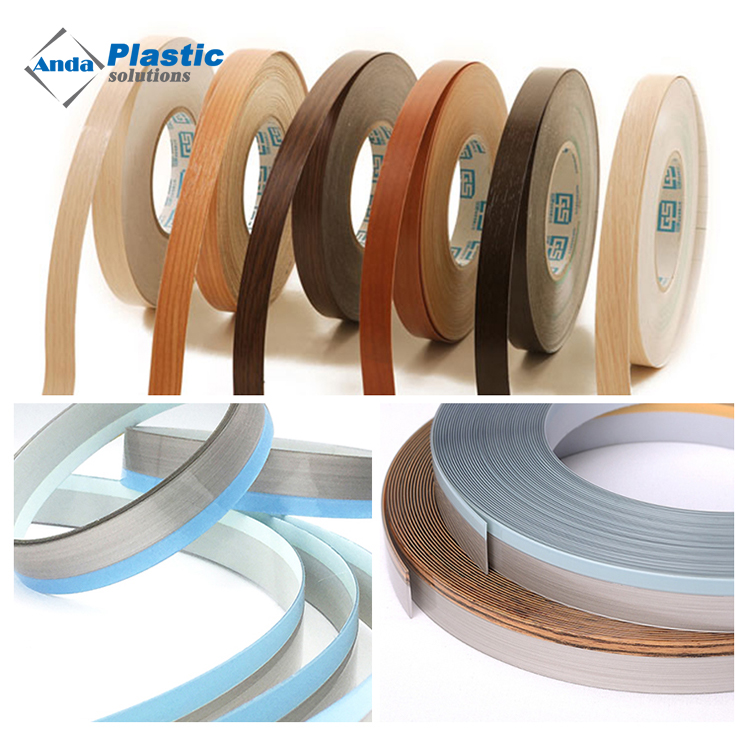

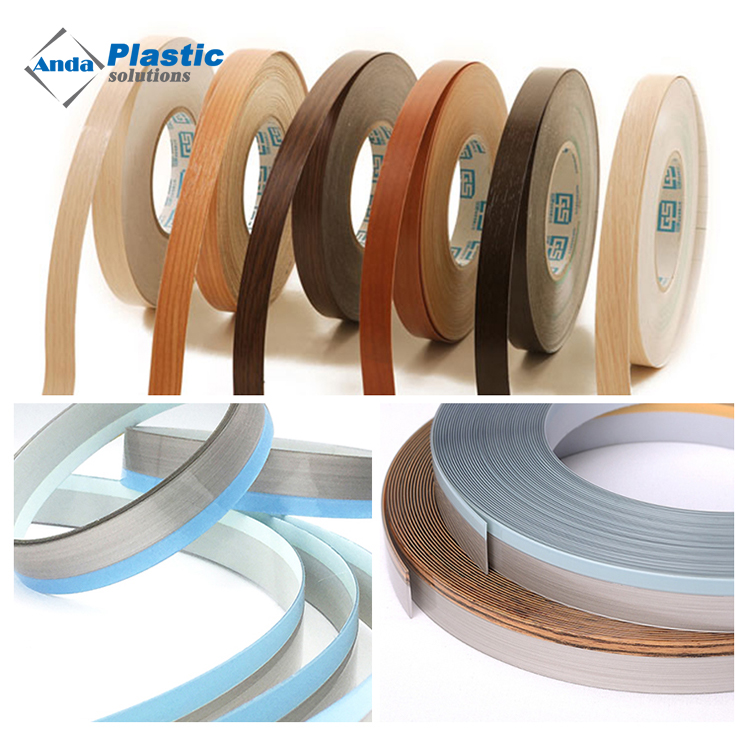

Residential furniture (kitchen cabinets, wardrobes, beds, tables).

Commercial interiors (office furniture, retail displays, hotel fixtures).

Woodworking projects (MDF/particleboard edge sealing, furniture repair, custom joinery).

Interior decoration (wall panels, door frames, flooring trims, closet organizers).

Anda Edge Banding Tape Manufacturing Machine

Built for durability, the edge banding tape manufacturing machine uses wear-resistant components in high-friction zones, reducing maintenance downtime by up to 40%. Its intuitive touchscreen interface simplifies operation, even for staff with minimal technical training. For businesses balancing speed, quality, and adaptability, this machine emerges as an indispensable asset in today’s competitive manufacturing landscape.

Main parameter of edge banding tape manufacturing machine

Model | SJSZ45 | SJSZ55 |

Extruder | 45/100 | 55/110 |

Output Cavities | 2 cavity | 4 cavity ,6 cavity or 8 cavity |

Capacity | 1.5-1.8 ton per day | 2.2 tons per day |

Company Profile

Anda company was established by professional, passionate & responsible peoples who has long time experience in china plastic machines industry, Since inception, Anda company team always believes that excellent product quality reasonable price and professional fast service is the basis for long term cooperation with our customers, Therefore, anda company apply very strict rule for quality, and make high standard level for product quality. At same time, we striving to reducepro-duction cost to offer better price to our customers, And, we also pay much attention to service, we consider service as importantas sales work, we continuously train cur service stuff, improve their service ability and service attitude, so that this team can provide in time, most professional service to each of our customer around the world.

Proven Reliability: Our equipment is manufactured with high-grade steel and imported components, undergoing rigorous quality testing to ensure stable performance under 24/7 operation.

Customization Capabilities: We collaborate with clients to design equipment tailored to their specific product needs—whether it’s custom profiles, unique textures, or specialized production capacities.

Global Compatibility: All machinery meets international standards (CE, ISO 9001) and supports universal voltage (220V/380V), making it suitable for export to Europe, Asia, Africa, the Middle East, and the Americas.

End-to-End Support: Our team provides pre-sales technical consultation, on-site installation, and after-sales maintenance (including spare parts supply within 48 hours for urgent needs), ensuring minimal downtime.

Cost-Effective Innovation: We combine advanced technology with competitive pricing, making high-performance production equipment accessible to SMEs and large enterprises alike.

Residential furniture (kitchen cabinets, wardrobes, beds, tables).

Commercial interiors (office furniture, retail displays, hotel fixtures).

Woodworking projects (MDF/particleboard edge sealing, furniture repair, custom joinery).

Interior decoration (wall panels, door frames, flooring trims, closet organizers).