| Availability: | |

|---|---|

| Quantity: | |

China

JINSE

PVC Wall Ceiling Panel Extrusion Line

Anda PVC wall ceiling panel making machine adopt many world famous parts such as ABB frequency converter, Siemens motor, JAC gear box, Schneider contactor and so on, as well as adopt PID control to guarantee the high efficiency of the production line. Our PVC wall panel making machine is made up of four parts, they are extruder, cooling table, hauling engine and cutting machine. It is used to produce PVC ceiling panel or PVC wall panel and they can be made in varies of specifications, like the width of 15cm, 20cm, 25cm, 30cm, 60cm.

If you need to do more processing like laminating, you can see that in our store.

Features of PVC ceiling making machine:

·High speed,double output than common PVC ceiling production line.greatly decrease the labour cost and electricity cost and manage cost.

Extruder adopts PVC ceiling dedicated screw with nation patent, makesure best plastisizing effect and high output

·Extruder speed and haul off speed controlled by ABB frequencycon-verter,saving power and easy adjusting speed

·Extruder temperature adopt PID control,temperature fluctuation self-adjusting,it realize the high automatic level

·High caco3 flling percentage,it can up to 250phr, formula cost isgreatly reduced and competitive advantage also greatly improved.

·Lower power consumption,it can save 25-30% electrical powercon-sumption comparing with most kind PVC ceiling production line.

·With online hot stamping,easy operation,saving labour.

Model of China Anda PVC ceiling making machine

Model | 48/113 super conical | 53/128 commom | 53/128 high speed | 65/132 high speed |

Product width | 200mm,250mm | 200mm,250mm,300mm | 200mm-300mm | 200mm,300mm,400mm,500mm,600mm |

Extruder | SJSZ48/113 | SJSZ53/128 | SJSZ53/128 | SJSZ65/132 |

Capacity per day | >800 m2 | >1200 m2 | >1600 m2 | >3300 m2 |

Please note the output capacity are for reference, it will verify according to the weight of ceiling panel and formula, cooling water and so on. | ||||

Product Details

1. PVC wall panel making machine--extruder

2. PVC wall panel making machine--cooling table

3. PVC wall panel making machine--hauling engine

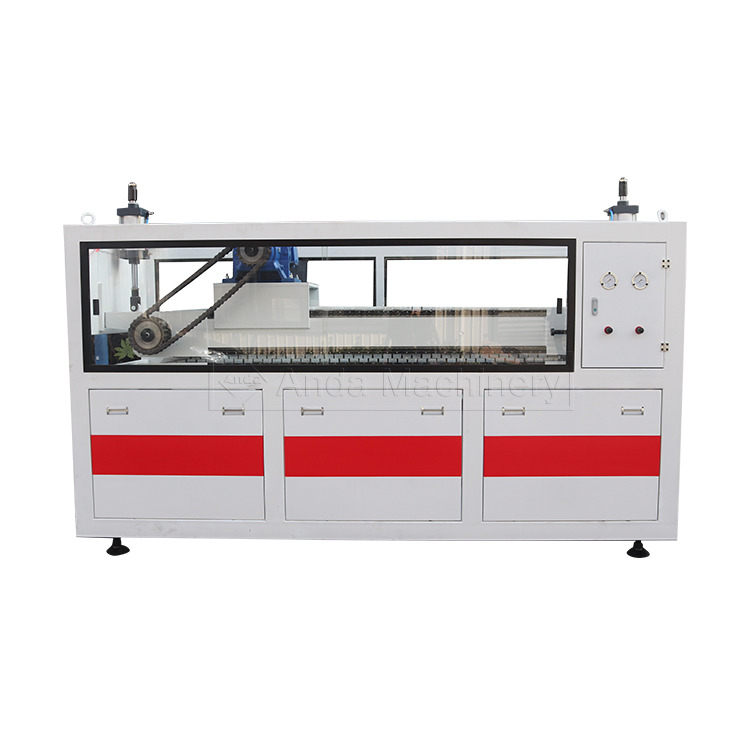

4. PVC wall panel making machine--cutting machine

1. PVC ceiling panel making process--extruding

(1) Adopt Siemens motor (effective control the starting current, lower staring power, reduce voltage fluctuation)

(2) Adopt JAC gear box (high efficiency, high bearing capacity, transfer smoothly, compact structure)(3) Adopt twin screw extruder (which use 38CrMoAL material -- high-wearing, high strength, high temperature resistance, corrosion resistance)

(4) Adopt PID control (temperature fluctuation self adjusting and realize the high automatic level)

(5) Adopt ABB frequency converter (control and regulate motor speed, stable performance, strong overlord capacity)

(6) Adopt Schneider contactor (high service life, high security)

2. PVC ceiling panel making process--cooling and finalizing

Adopt vacuum system to help the PVC products fast finalization and guarantee it is not out of shape.

3. PVC wall panel making process--hauling

The material of hauling is not too hard which can well protect the transfer of product. It could help the effective traction.

4. PVC wall panel making process--cutting

The blade is hard and sharp which has high efficiency and long service time. It also adopt sensing system and easy to cooperate.

Main Features of PVC ceiling and wall panel production line:

1.High speed, double output than common PVC ceiling production line, greatly decrease the labour cost and electricity cost and manage cost.

2.Extruder adopts PVC ceiling dedicated screw, make sure best plastisizing effect

3.Extruder speed and haul off speed controlled by ABB frequency converter, saving power and easy adjusting speed

4.Extruder temperature adopt PID control, temperature fluctuation self adjusting, it realize the high automatic level

5.The caco3 filler can up to 300phr, formula cost is greatly reduced.

6.Equipped with infrared tracking device which can eliminate the problem of fluctuation of extrusion flow rate, further can make sure get best product

7.Lower power consumption,it can save 25-30% electrical power consumption comparing with most kind PVC ceiling production line.

8.With online hot stamping, easy operation, saving labour.

Model of high speed PVC wall panel making machine

PVC Wall Ceiling Panel Extrusion Line

Anda PVC wall ceiling panel making machine adopt many world famous parts such as ABB frequency converter, Siemens motor, JAC gear box, Schneider contactor and so on, as well as adopt PID control to guarantee the high efficiency of the production line. Our PVC wall panel making machine is made up of four parts, they are extruder, cooling table, hauling engine and cutting machine. It is used to produce PVC ceiling panel or PVC wall panel and they can be made in varies of specifications, like the width of 15cm, 20cm, 25cm, 30cm, 60cm.

If you need to do more processing like laminating, you can see that in our store.

Features of PVC ceiling making machine:

·High speed,double output than common PVC ceiling production line.greatly decrease the labour cost and electricity cost and manage cost.

Extruder adopts PVC ceiling dedicated screw with nation patent, makesure best plastisizing effect and high output

·Extruder speed and haul off speed controlled by ABB frequencycon-verter,saving power and easy adjusting speed

·Extruder temperature adopt PID control,temperature fluctuation self-adjusting,it realize the high automatic level

·High caco3 flling percentage,it can up to 250phr, formula cost isgreatly reduced and competitive advantage also greatly improved.

·Lower power consumption,it can save 25-30% electrical powercon-sumption comparing with most kind PVC ceiling production line.

·With online hot stamping,easy operation,saving labour.

Model of China Anda PVC ceiling making machine

Model | 48/113 super conical | 53/128 commom | 53/128 high speed | 65/132 high speed |

Product width | 200mm,250mm | 200mm,250mm,300mm | 200mm-300mm | 200mm,300mm,400mm,500mm,600mm |

Extruder | SJSZ48/113 | SJSZ53/128 | SJSZ53/128 | SJSZ65/132 |

Capacity per day | >800 m2 | >1200 m2 | >1600 m2 | >3300 m2 |

Please note the output capacity are for reference, it will verify according to the weight of ceiling panel and formula, cooling water and so on. | ||||

Product Details

1. PVC wall panel making machine--extruder

2. PVC wall panel making machine--cooling table

3. PVC wall panel making machine--hauling engine

4. PVC wall panel making machine--cutting machine

1. PVC ceiling panel making process--extruding

(1) Adopt Siemens motor (effective control the starting current, lower staring power, reduce voltage fluctuation)

(2) Adopt JAC gear box (high efficiency, high bearing capacity, transfer smoothly, compact structure)(3) Adopt twin screw extruder (which use 38CrMoAL material -- high-wearing, high strength, high temperature resistance, corrosion resistance)

(4) Adopt PID control (temperature fluctuation self adjusting and realize the high automatic level)

(5) Adopt ABB frequency converter (control and regulate motor speed, stable performance, strong overlord capacity)

(6) Adopt Schneider contactor (high service life, high security)

2. PVC ceiling panel making process--cooling and finalizing

Adopt vacuum system to help the PVC products fast finalization and guarantee it is not out of shape.

3. PVC wall panel making process--hauling

The material of hauling is not too hard which can well protect the transfer of product. It could help the effective traction.

4. PVC wall panel making process--cutting

The blade is hard and sharp which has high efficiency and long service time. It also adopt sensing system and easy to cooperate.

Main Features of PVC ceiling and wall panel production line:

1.High speed, double output than common PVC ceiling production line, greatly decrease the labour cost and electricity cost and manage cost.

2.Extruder adopts PVC ceiling dedicated screw, make sure best plastisizing effect

3.Extruder speed and haul off speed controlled by ABB frequency converter, saving power and easy adjusting speed

4.Extruder temperature adopt PID control, temperature fluctuation self adjusting, it realize the high automatic level

5.The caco3 filler can up to 300phr, formula cost is greatly reduced.

6.Equipped with infrared tracking device which can eliminate the problem of fluctuation of extrusion flow rate, further can make sure get best product

7.Lower power consumption,it can save 25-30% electrical power consumption comparing with most kind PVC ceiling production line.

8.With online hot stamping, easy operation, saving labour.

Model of high speed PVC wall panel making machine