| Availability: | |

|---|---|

| Quantity: | |

China

JINSE

Decoration PVC Marble Sheet Making Machine is applied to produce PVC sheet with width of 1220mm and length with 2440mm, thickness mostly from 2.5 to 4mm. The surface of PVC sheet generally treated by hot stamping or lamination, then coated by UV varnish. By switching film with different color. After coating UV glossy varnish, the surface of PVC sheet is more smooth and wearable. It can also produce LVT floor by some adjustment and with related auxiliary machines.

Main parameter of PVC marble sheet making machine:

| Item | Parameter | |

| Extruder | 80/156 | 92/188 |

| Thickness of Sheet | 2.8-3.5mm | 2-6mm |

| Size of Sheet | 1220*2440mm | 950*2440mm |

| Weight of Sheet | 17-25kg/piece | 12-36kg/piece |

| Output | 530 sheets/day (10T/24h) | 800 sheets/day (12-15T/24h) |

| Size of Machine | 25*2.5*3m | 28*2.5*3m |

| Suggested Workshop Size | 60*24*6m | 60*24*6m |

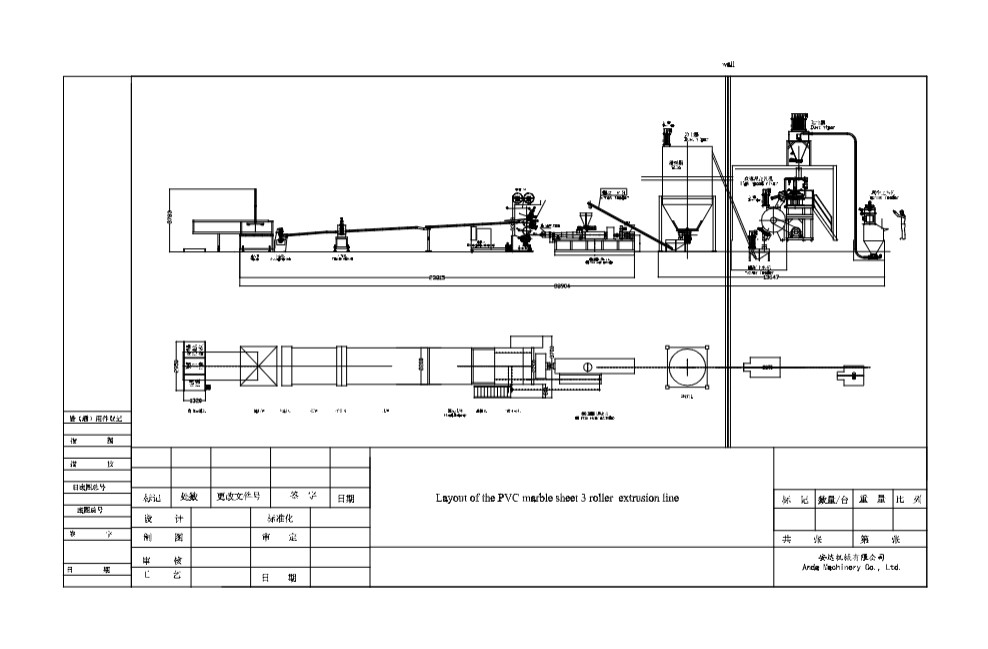

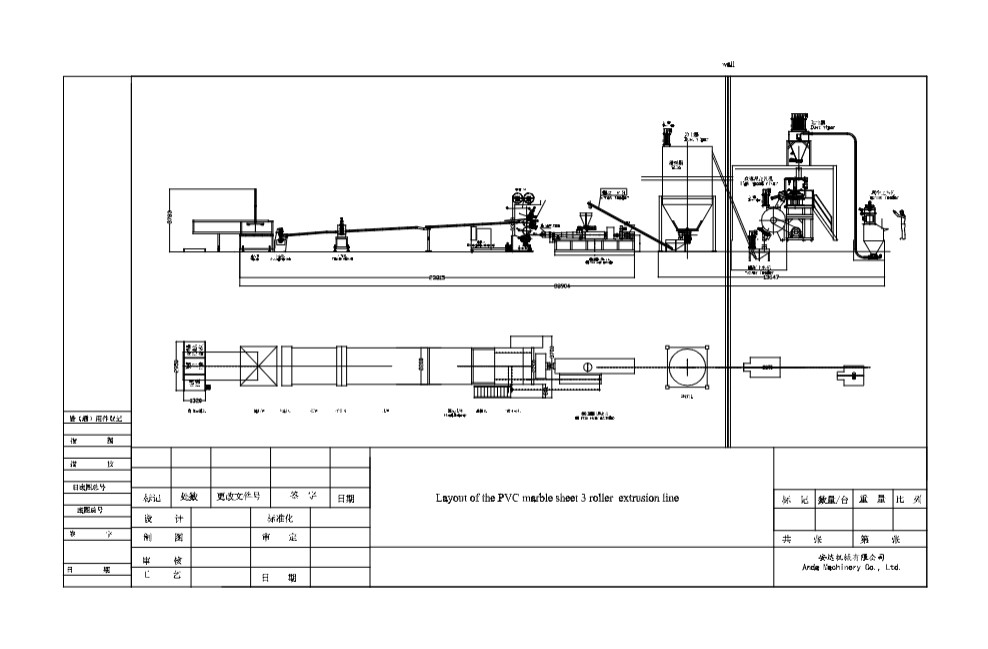

Whole factory layout of PVC marble sheet proudction line:

Decoration PVC Marble Sheet Making Machine is applied to produce PVC sheet with width of 1220mm and length with 2440mm, thickness mostly from 2.5 to 4mm. The surface of PVC sheet generally treated by hot stamping or lamination, then coated by UV varnish. By switching film with different color. After coating UV glossy varnish, the surface of PVC sheet is more smooth and wearable. It can also produce LVT floor by some adjustment and with related auxiliary machines.

Main parameter of PVC marble sheet making machine:

| Item | Parameter | |

| Extruder | 80/156 | 92/188 |

| Thickness of Sheet | 2.8-3.5mm | 2-6mm |

| Size of Sheet | 1220*2440mm | 950*2440mm |

| Weight of Sheet | 17-25kg/piece | 12-36kg/piece |

| Output | 530 sheets/day (10T/24h) | 800 sheets/day (12-15T/24h) |

| Size of Machine | 25*2.5*3m | 28*2.5*3m |

| Suggested Workshop Size | 60*24*6m | 60*24*6m |

Whole factory layout of PVC marble sheet proudction line:

Premium PVC Marble Sheet Production Line: Advanced Machinery for Artificial Marble Manufacturing

As a trusted provider of PVC Marble Sheet Production Line and high-performance pvc marble sheet machine, we deliver turnkey solutions for producing top-grade artificial marble sheets that blend aesthetic appeal with practicality. Our cutting-edge pvc marble sheet making machine range is engineered to cater to global decorative material industries, with tailored designs to fit regional market demands across Asia-Pacific, Europe, Middle East, Africa, and North America. Both our pvc artificial marble sheet machine and pvc imitation marble sheet machine adhere to international quality and environmental standards, empowering businesses to gain a competitive edge in the booming artificial marble market.

Automatic Material Mixing System: A foundational part of the pvc marble sheet making machine, it features dual hot-cool mixing tanks with intelligent temperature control (50-120℃). This system achieves uniform blending of PVC powder, additives, and colorants, laying the groundwork for high-quality sheet production. It supports a mixing capacity of 600-800 kg/h, suitable for both small and large-scale factories.

High-Torque Extruder: As the core of the pvc marble sheet machine, the twin-screw extruder adopts wear-resistant alloy steel screws and precise temperature zoning control. It ensures full plasticization of raw materials, eliminating bubbles and impurities in the sheet. This component is fully compatible with both pvc artificial marble sheet machine and pvc imitation marble sheet machine workflows, with adjustable extrusion speed (0-5 m/min).

Precision Calendering & Texturing Unit: Equipped with three chrome-plated rollers, this unit shapes the sheet and imprints natural marble textures. It supports online film lamination, enhancing the sheet’s scratch resistance and glossiness. For pvc marble sheet making machine users, the roller patterns are replaceable to meet diverse design needs across regions.

Continuous Cooling & Cutting System: The water-cooled conveyor belt rapidly stabilizes the sheet’s shape, while the automatic cutting machine trims edges with high precision (error ≤0.5mm). This system reduces labor input and improves production efficiency, a key advantage for markets with high labor costs like Europe and North America.

Eco-Friendly Recycling Unit: An optional add-on for the PVC Marble Sheet Production Line, it crushes production scraps into reusable powder, reducing material waste by up to 35%. This aligns with environmental regulations in eco-sensitive markets and lowers overall production costs.

Premium PVC Marble Sheet Production Line: Advanced Machinery for Artificial Marble Manufacturing

As a trusted provider of PVC Marble Sheet Production Line and high-performance pvc marble sheet machine, we deliver turnkey solutions for producing top-grade artificial marble sheets that blend aesthetic appeal with practicality. Our cutting-edge pvc marble sheet making machine range is engineered to cater to global decorative material industries, with tailored designs to fit regional market demands across Asia-Pacific, Europe, Middle East, Africa, and North America. Both our pvc artificial marble sheet machine and pvc imitation marble sheet machine adhere to international quality and environmental standards, empowering businesses to gain a competitive edge in the booming artificial marble market.

Automatic Material Mixing System: A foundational part of the pvc marble sheet making machine, it features dual hot-cool mixing tanks with intelligent temperature control (50-120℃). This system achieves uniform blending of PVC powder, additives, and colorants, laying the groundwork for high-quality sheet production. It supports a mixing capacity of 600-800 kg/h, suitable for both small and large-scale factories.

High-Torque Extruder: As the core of the pvc marble sheet machine, the twin-screw extruder adopts wear-resistant alloy steel screws and precise temperature zoning control. It ensures full plasticization of raw materials, eliminating bubbles and impurities in the sheet. This component is fully compatible with both pvc artificial marble sheet machine and pvc imitation marble sheet machine workflows, with adjustable extrusion speed (0-5 m/min).

Precision Calendering & Texturing Unit: Equipped with three chrome-plated rollers, this unit shapes the sheet and imprints natural marble textures. It supports online film lamination, enhancing the sheet’s scratch resistance and glossiness. For pvc marble sheet making machine users, the roller patterns are replaceable to meet diverse design needs across regions.

Continuous Cooling & Cutting System: The water-cooled conveyor belt rapidly stabilizes the sheet’s shape, while the automatic cutting machine trims edges with high precision (error ≤0.5mm). This system reduces labor input and improves production efficiency, a key advantage for markets with high labor costs like Europe and North America.

Eco-Friendly Recycling Unit: An optional add-on for the PVC Marble Sheet Production Line, it crushes production scraps into reusable powder, reducing material waste by up to 35%. This aligns with environmental regulations in eco-sensitive markets and lowers overall production costs.