| Availability: | |

|---|---|

| Quantity: | |

China

JINSE

Anda PVC Marble Sheet Production Line

PVC sheet is widely used in hotel, office building, supermarket, KTV, massage club and other public areas.

Comparing with natural board and MDF sheet, PVC Marble Sheet has the following advantages:

1. Cheap cost

2. Water-proof, insect prevention, moth proof

3. Easy and faster installation

4. Vivid color and glossy

5. Environment protection and no pollution

Main parameter of PVC Marble Sheet Production Line

| Item | Parameter | |

| Extruder | 80/156 | 92/188 |

| Thickness of Sheet | 2.8-3.5mm | 2-6mm |

| Size of Sheet | 1220*2440mm | 950*2440mm |

| Weight of Sheet | 17-25kg/piece | 12-36kg/piece |

| Output | 530 sheets/day (10T/24h) | 800 sheets/day (12-15T/24h) |

| Size of Machine | 25*2.5*3m | 28*2.5*3m |

| Suggested Workshop Size | 60*24*6m | 60*24*6m |

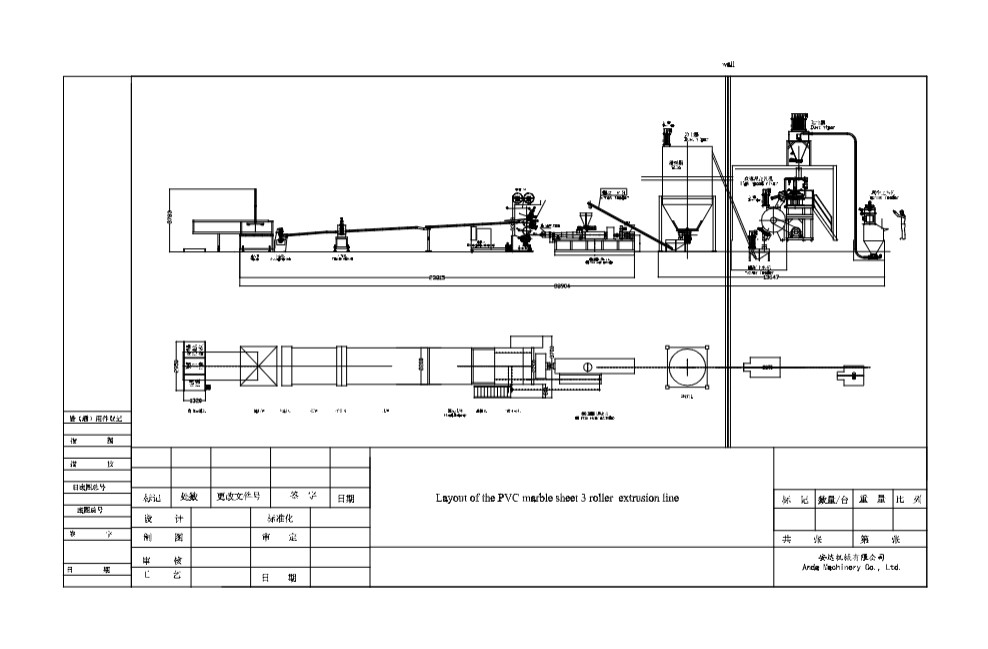

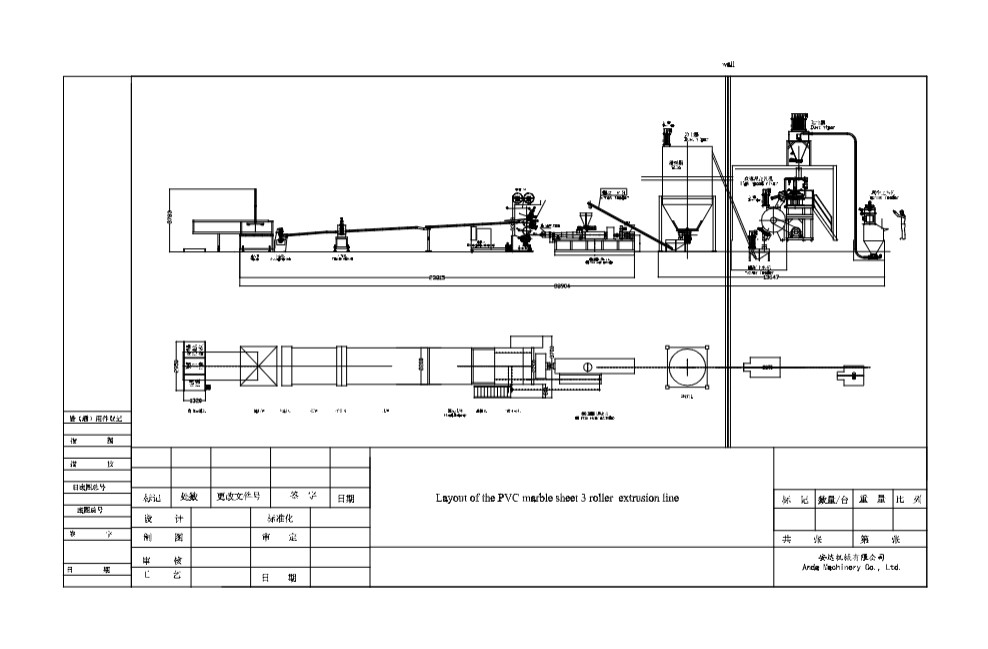

Whole factory layout of PVC marble sheet proudction line

1. PVC Marble Sheet Production Line making process--extruding

2. PVC Marble Sheet Production Line process--calendaring

3. PVC Marble Sheet Production Line process--hot stamping

4. PVC Marble Sheet Production Line process--cooling

5. PVC Marble Sheet Production Line process--cutting and automatic stacking

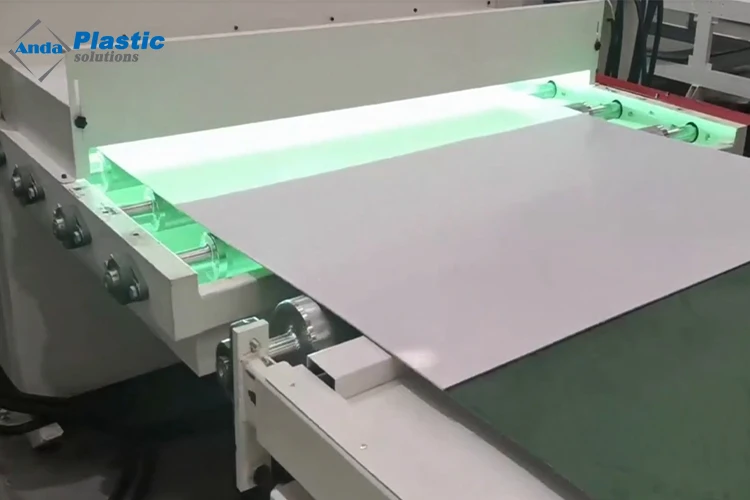

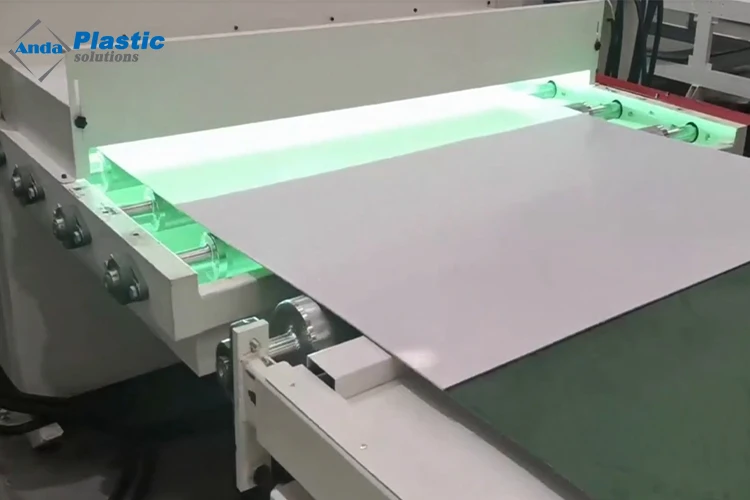

6. PVC Marble Sheet Production Line process--UV coating

7. PVC Marble Sheet Production Line process--final product display

About ANDA Machinery:

More keywords: PVC Marble Sheet Production Line, pvc marble sheet machine, pvc marble sheet making machine, pvc artificial marble sheet machine, pvc imitation marble sheet machine

Anda PVC Marble Sheet Production Line

PVC sheet is widely used in hotel, office building, supermarket, KTV, massage club and other public areas.

Comparing with natural board and MDF sheet, PVC Marble Sheet has the following advantages:

1. Cheap cost

2. Water-proof, insect prevention, moth proof

3. Easy and faster installation

4. Vivid color and glossy

5. Environment protection and no pollution

Main parameter of PVC Marble Sheet Production Line

| Item | Parameter | |

| Extruder | 80/156 | 92/188 |

| Thickness of Sheet | 2.8-3.5mm | 2-6mm |

| Size of Sheet | 1220*2440mm | 950*2440mm |

| Weight of Sheet | 17-25kg/piece | 12-36kg/piece |

| Output | 530 sheets/day (10T/24h) | 800 sheets/day (12-15T/24h) |

| Size of Machine | 25*2.5*3m | 28*2.5*3m |

| Suggested Workshop Size | 60*24*6m | 60*24*6m |

Whole factory layout of PVC marble sheet proudction line

1. PVC Marble Sheet Production Line making process--extruding

2. PVC Marble Sheet Production Line process--calendaring

3. PVC Marble Sheet Production Line process--hot stamping

4. PVC Marble Sheet Production Line process--cooling

5. PVC Marble Sheet Production Line process--cutting and automatic stacking

6. PVC Marble Sheet Production Line process--UV coating

7. PVC Marble Sheet Production Line process--final product display

About ANDA Machinery:

More keywords: PVC Marble Sheet Production Line, pvc marble sheet machine, pvc marble sheet making machine, pvc artificial marble sheet machine, pvc imitation marble sheet machine