Heating and Cooling PVC mixer compound machine is widely used to mix PVC powder with some other materials in the industry of PVC pipe, PVC profile, PVC board/sheet, WPC material batching compounding and so on.

Anda Decoration PVC Artificial Marble Sheet Machine is applied to produce PVC sheet with width of 1220mm and length with 2440mm, thickness mostly from 2.5 to 4mm. The surface of PVC sheet generally treated by hot stamping or lamination, then coated by UV varnish. By switching film with different color. After coating UV glossy varnish, the surface of PVC sheet is more smooth and wearable. It can also produce LVT floor by some adjustment and with related auxiliary machines.

Decoration PVC Marble Sheet Making Machine is applied to produce PVC sheet with width of 1220mm and length with 2440mm, thickness mostly from 2.5 to 4mm. The surface of PVC sheet generally treated by hot stamping or lamination, then coated by UV varnish. By switching film with different color. After coating UV glossy varnish, the surface of PVC sheet is more smooth and wearable. It can also produce LVT floor by some adjustment and with related auxiliary machines.

LVT floor production line mainly produces LVT floor with 1200mm wide and 1.5-3mm thick. It has the advantages of high degree of automation, simple operation, stable and reliable production operation and high yield.

PVC door and window profile making machine mainly composed by conical Twin Screw Extruder, Cooling Table, Hauling Machine, Cutting Machine, Stacker. With different moulds, it can produce various UPVC profile, such as: PVC window door profile, PVC wall panel, PVC window sill board, cabinet door board, curtain box, PVC trucking, cable duct, PVC skirting, PVC protection corner and so on.

And by changing screw barrel and mould, it can also produce PVC based WPC products, such as: WPC wall panel, WPC window door frame moldings, skirting moldings, WPC door board etc.

PVC cable trunking extrusion machine /production line /making machine is mainly used for making small PVC profile, such as PVC Skirting profile,wall corner profile,PVC cable trunking profile with different section shape and height. the surface of PVC profile/panel can be treated by printing & coated with glossy oil, or by heat transfer printing, or by lamination, which can make good decoration effect for kitchen,toilet,balcony and so on

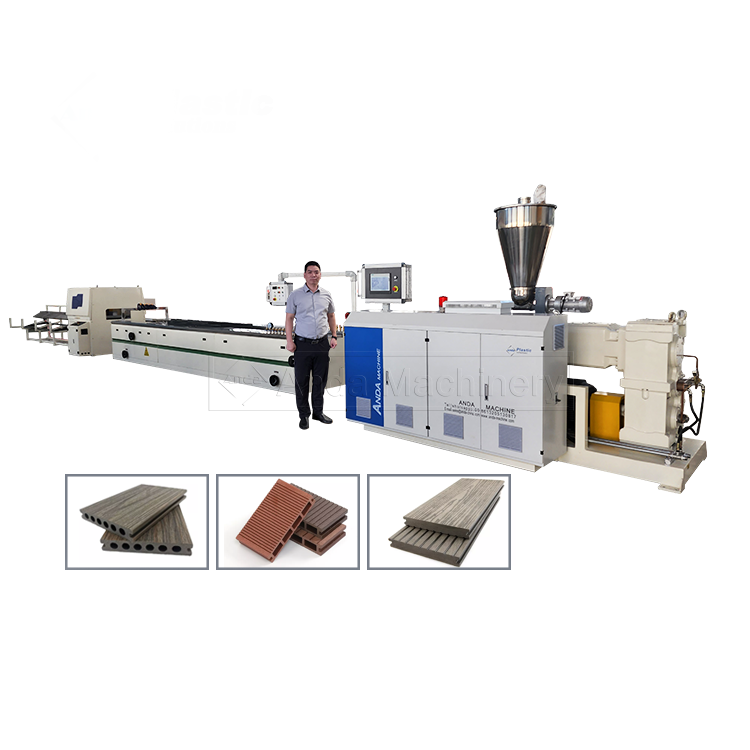

WPC wall panel making machine is used to making various WPC panels. It’s mainly composed by conical twin screw extruder, vacuum calibration table, haul off machine, cutting machine and stacker.

WPC wall panel is one of the most popular new type wall panel in the market. It is a high-tech new type of green environmental protection decoration material. It based on wood (wood fiber and plant fiber) material, mixing with thermoplastic polymer material (plastic) and processing AIDS, etc., WPC panel has the performance and characteristics of both wood and plastic, it is a new kind of composite material substitute for wood and plastic.

WPC wall panel is widely used in rooms, hotels, entertainment places, offices, laboratories and other places.

WPC louver panels production line is used for making WPC louver panels which is now a popular product applied in decoration. It could help the decoration more exquisite and improve a level.

WPC louver panels making machine including four main parts, they are twin screw extruder, vacuum calibrator, hauling engine and cutting machine. Anda Machinery use world famous band of motor, engine, gearbox to produce and guarantee the quality of machine.

Anda PVC wall ceiling panel making machine adopt many world famous parts such as ABB frequency converter, Siemens motor, JAC gear box, Schneider contactor and so on, as well as adopt PID control to guarantee the high efficiency of the production line. Our PVC wall panel making machine is made up of four parts, they are extruder, cooling table, hauling engine and cutting machine. It is used to produce PVC ceiling panel or PVC wall panel and they can be made in varies of specifications, like the width of 15cm, 20cm, 25cm, 30cm, 60cm.

If you need to do more processing like laminating, you can see that in our store.

UPVC ceiling panel production line is used to produce PVC ceiling tiles with 595x595, 600×600 , 603x603. The surface of PVC ceiling tile can be treated by to hot stamping for different color or patterns to fit various decoration style.

65/132 PVC Plastic Extruder is applied to produce rigid PVC profile, PVC sheet, PVC board, PVC pipe, PVC pelletizing and so on.

Anda Twin screw Pvc Edge Banding Production Line is used to produce PVC edge band, it's widely used for edge sealing of MDF, HDF, particle board, composite board and so on.

PVC edge band production line with Calender Cooling is used to produce PVC edge band with different width, section shape and thickness. The surface of PVC edge band can be treated by three color printing & coated with glossy oil, or by heat transfer printing.

UPVC door making machine is applied to produce UPVC door board with width of 700mm, 800mm etc, The capacity of UPVC window profile extrusion production line has high capacity up to 10000kg/day, which equal to 400 -500 door boards per day.

PVC pipe making machine is used to produce UPVC/PVC pipe with diameter from 16 up to 800mm, which is used for electric conduit, building drainage, sewage pipe, water supply pipe, well casing pipe, agricultural irrigation pipe and so on.

It’s mainly composed by conical twin screw extruder, mould, vacuum calibration tank, haul off machine, cutting machine, stacker, belling machine.

By changing dorn or mould lip, it can produce several diameter or wall thickness on same machine.

PVC conduit pipe making machine is used to produce UPVC/PVC electric conduit. It’s mainly composed by conical twin screw extruder, mould, vacuum calibration tank, haul off machine, cutting machine, stacker, belling machine.

By changing dorn or mould lip, it can produce several diameter or wall thickness on same machine.

English

English